These are blocks made up to hold the tubing in place on the table while being welded. Made up about 20 for 5/8" tubing, 15 for 3/4" tubing and 10 for 1/2" tubing.Some of the blocks were made to hold the tubing right on the edge of the table. 1/16" and 1/8" plywood shims are inserted under blocks to keep the tubing on the centerline.

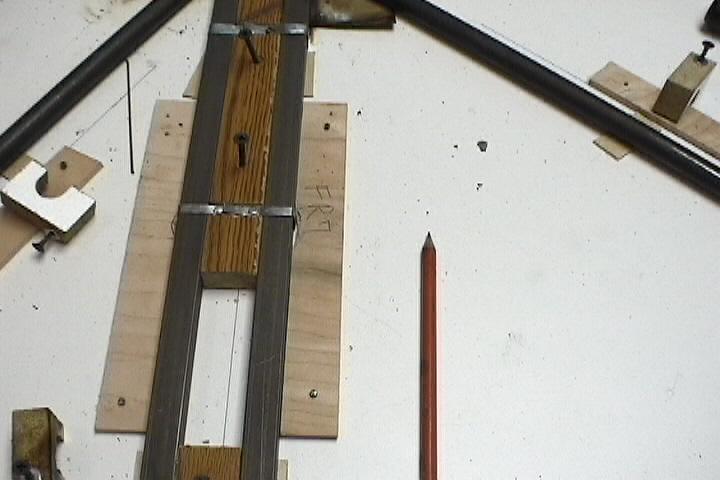

This shows how the hold down blocks are being used.The blocks were made with one edge 1"off the center line of the tubing. Staight strips of 1/4" luan plywood are tacked on the table as guides for the blocks. The blocks on the right are holding the tubing on the edge of the straight edge of the table.

Here you can see the lines drawn for the fuselage side on the table. Notched tubing is set in place to check fit. Tubing templates are still on tubing to give the correct orientation.

This is the rectangular tubing on the fuselage side that the main carry through assembly mounts to. Scrap wood spacers were made to hold the correct gap and luan ply tacked along the sides to hold the correct psition. 1/16" shims are under the 5/8" tube to keep it on the center of the 3/4" longerons.

Layout lines are drawn on the table. Luan ply strips are offset 1" from center lines of tubing. Shims are placed under tubing. Notched tubing is being checked for fit before screwing blocks down to table.

White dot is put on the tubing so that it can be placed back in the correct orientation. This 1/2" tube requires a 1/8" shim off the table to keep the centerline.

The tubing are all in place and checked for fit. White dots are put on tubing for correct orientation. Once checked out the paper templates are removed and the ends of the tubing cleaned up for welding.

In order to get a complete weld around the tubing at any cluster a certain sequence has to be folllowed. Here the hidden crotch of the upright will be fullly welded before diagonal is tacked in.

This is a hidden crotch that is fully welded were a diagonal comes in at.

Getting ready to put the sides together. Blocks are holding the sides to the edge of the 24" wide table.

The sides can be pivoted down to the table in the hold down blocks to check the alignment of the rectangular tubing for the main carry through. The 2 ply strips on the table are the position of the main carry through. The longerons are marked at the hold down blocks to keep a check on alignment during assembly of top and bottom tubes.